What’s the Right Motor for a Belt Grinder?

If you buy a motor from us, it will be a Single or Three Phase IEC, 2HP, 230V, 90-Frame, 2-Pole motor with a B3 mount. If it is single phase, it will have a permanent capacitor. But you may like to use your own motor for your project, so let’s break those specifications down and discuss what each of those things actually mean, and why we chose those for our belt grinder.

Single or Three Phase

Across the world, domestic power is overwhelmingly supplied as single-phase power. Generally speaking, if you have three phase power, you will know, as it is typically found in industrial settings to supply heavy loads. The engineering miracle of power distribution and the physics of electric motors is an interesting topic of it’s own, but insofar as it effects your belt grinder project, there is functional difference in performance between a single phase and three phase motor.

The reason many people choose a 3-phase motor is to allow for speed control. By using a VFD (Variable Frequency Drive), you can use a domestic single-phase power supply to power a 3-phase motor, while also being able to electronically control the speed of the motor. This kind of speed control is not practical on a single-phase motor. A VFD (also referred to as an ‘Inverter’) controls the speed of the motor by adjusting the frequency of the power supplied to the motor. This results in minimal loss of torque. By comparison, trying to control the motor speed by supplying it with a lower voltage will result in a rapid drop in torque, making the machine non-functional.

Single Phase = Fixed Speed

Three Phase + VFD = Variable Speed (and only requires a single-phase power supply)

IEC and NEMA Motors

Modern AC motors are typically found in two main configurations; IEC and NEMA. These are standards, not companies, and simply define the physical characteristics of the motor. Both can be found in a multitude of different configurations, and neither is automatically preferable over the other. Quite simply, NEMA motors are used almost exclusively in North America as the standard is set by the National Electrical Manufacturers Association of the USA. IEC is the most common standard of motor across the world, set by the wonderfully named International Electrotechnical Commission. Most motor parts are highly standardised, and parts like faces, fan shrouds and feet are interchangeable within their own standard.

Integrated Cooling Fins

Defined in Metric Units (90-frame shaft diameter is 24mm)

If present, capacitor is stored within the connection box

Lubricated with Lithium Grease

Shaft seal and totally enclosed design as standard

IEC

Typically smooth exterior

Defined in Imperial units (56-frame shaft diameter is 5/8”)

If present, capacitor is stored separately from the connection box

Lubricated with Polyuera Grease

Different levels of ingress protection available, for belt grinders, TEFC (totally enclosed, fan cooled) is vital

NEMA

The CORVUS features a fully removable motor plate and support for foot-mounted motors, so it is easy to modify almost any foot-mounted motor to work. If you have special requirements, we will be able to fabricate you a custom motor plate.

IEC Motors:

90-Frame (Long or Short)

80-Frame

NEMA Motors:

56-Frame

For the CORVUS

Frame Size and Mounts

A motor frame size is a byproduct of its specifications. Frame sizes are highly standardised to ensure the interchangeability of motors on machinery. Both the IEC and NEMA standards have their own set of frame sizes, which in turn dictate the dimensions of the mounts.

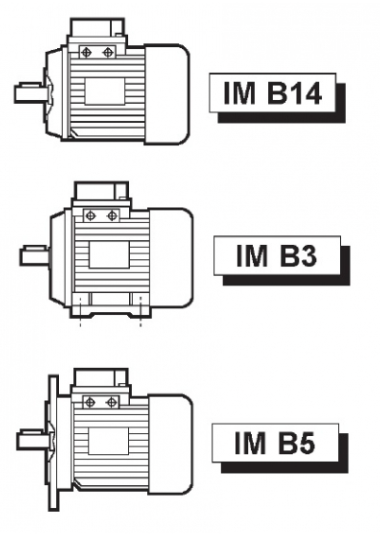

The ‘B’ prefix on an IEC motor denotes the mounting standard:

B3 = Foot Mounted

B5 = Flange Mounted

B14 = Face Mounted

B34 = Foot & Face Mounted

B35 = Foot & Flange Mounted

Voltage (and frequency)

We supply 230V Motors, these are compatible with standard UK and EU domestic power, as well as as 220-240V supplies across the world. For North American customers, you will need to have an available 240V outlet if you wish to use one of the motors we supply. If this is not possible, then I would encourage you to source a NEMA 56-120V motor locally.

If you are using a 3-phase motor with a VFD, you will need to set the motor to a Delta Configuration according to your motor’s manual.

The motors we supply will run on a 50Hz (UK, EU) or 60Hz (NA) supply. With a VFD, you can set the frequency anywhere between 0-90Hz.

Number of Poles / RPM

The number of magnetic poles on a motor, along with frequency, determine the speed of a motor. Motors in the power range relevent to us are usually found with 2, 4, or sometimes 6 poles, and the number of poles relates inversely, which is to say that the fewer poles, the faster the motor speed. Poles are not like gears, increasing the number of poles may slow the motor speed, but it does not have a discernable increase in torque.

You can use this calculator to work out your belt speed

The speed of a motor should be chosen based on the target belt speed, and has to factor in the diameter of the drive wheel. For a fixed-speed motor, we recommend aiming for a SFPM (surface feet per minute) of 3000-4000. This gives good results on steel, but is not too fast to make final bevelling of knives, or work with wood or plastics too difficult, where a high speed can cause overheating of a heat-treated edge, or burning or melting of other materials.

A 2-pole motor gives us an acceptable range of fixed belt speeds using our 100mm drive wheels on both 50Hz and 60Hz supplies. Using a VFD gives a greater degree of control of the belt.

Permanent or Dual-Capacitor?

A capacitor start/capacitor run (dual-cap) motor uses two separate capacitors, one to start the motor, and then once a certain RPM has been reached, another to keep it running. These motors have a greater starting torque, but are more complex and expensive compared to permenent capacitor motors.

Perm cap have a single capacitor that handles both startup and steady-state operation. While the starting torque is lower than with their twin-cap counterparts, this extra starting torque provides no benefit for use on belt grinders, as the starting torque requirement is low.